In 2003 we went to Colombia to begin working on an export business, leveraging family assets and knowledge in Latin American business to form Old Spanish Main, Ltda. a licensed cultivator and exporter in partnership with with La Federación Nacional de Cafeteros de Colombia. We worked diligently at the farms in Huila, Colombia working on improving the soil, condition of the plants and fields. Our goal was to produce some of the finest Colombian coffees available, and benefiting the people that directly worked the fields in as much as possible.

There’s an incredible amount of knowledge and experience required to produce high-grade export coffee. One thing that people don’t understand is that it’s very difficult to predict exactly what the weather is going to do for you, so while you might produce a spectacular coffee one year, the next could be a complete disaster, even with similar weather and farming conditions. Unlike some other products, coffee is very sensitive to being damaged at literally any point in the process from the planting to the cup.

Shane Lewis, founded Old Spanish Main, Ltda. in Bogotá, Colombia to function as an export operation, Certified by La Federación Nacional de Cafeteros de Colombia. They had family & regional farms in Huila, Colombia working to cultivate some of the finest Colombian coffee available.

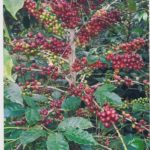

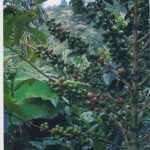

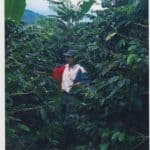

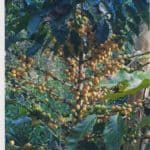

We went to lengthy steps to control quality, from ensuring the fields were free of weeds with several de-weedings per year, to paying the coffee harvesters double to take their time and only pick the ripe coffee cherries. The immature fruits would often carelessly get pulled into the collection bag, which can taint the cup in the end. The following photos are from our farms in Huila, Colombia.

Preparing the fields

Planting plantains amongst your coffee plants can provide valuable nutrients in a synergistic type of relationship. Not only can you increase the productivity of the land, the plantain with it’s large leaves produces shade and shelter which benefits the coffee plant. A recommended interval is 2 coffee trees per plantain tree.

In addition to the actual plantains produced, these plants provide nutrients and mulch for the mutual benefit of the soil. These effect to increase the resilience of the coffee production operation, and can be particular benefit when rainfall is scarce and or irregular.

Root systems produced by both the coffea plant and the plantain serve to reinforce the soil and minimize erosion on the high altitude Colombian hillsides.

Altitude also has a great effect on the flavor of the coffees as well as production. This needs to be taken into consideration, as it produces a harder, smaller bean. This typically can make the bean more flavorful as the sugars are more compacted within the dense bean, but when coffee is sold by weight, this can mean less production for the harvest.

The harvest

Harvesting goes on all throughout the harvest season continually as beans mature at different times. For this reason, regular passes through the fields make coffee one of the most expensive drinks in the world to produce.

Afterwards, we run the coffee through a depulping machine to remove the fruit, which serves little purpose beyond putting it back into the soil to serve as organic fertilizer, benefiting future harvests. Much like a peach or a grape, the coffee fruit has a dicot seed, producing two coffee beans per fruit. As such you can imagine how time consuming it is to produce a large volume of coffee.

Colombia is one of the few countries in the world that enjoys a November and a March coffee harvest. Most other countries only see a single yearly harvest. Colombian coffee sells for a .02 cent premium on the coffee market.

After depulping the coffee must be fermented inside a water tank. Using clean water, free of odor and taint is essential to maintaining the quality control as this can effect the taste in the cup even at this stage. Typically, the worker will leave this coffee in the fermentation tank for 16 hours then remove the coffee and set it out to the patios to dry.

Naturally, we insisted on getting the coffee out of the tank at the 16 hour mark as excessive fermentation can cause sourness among other taints in the cup. This fermentation process removes the slimy mucilage from the outside of the bean.

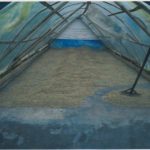

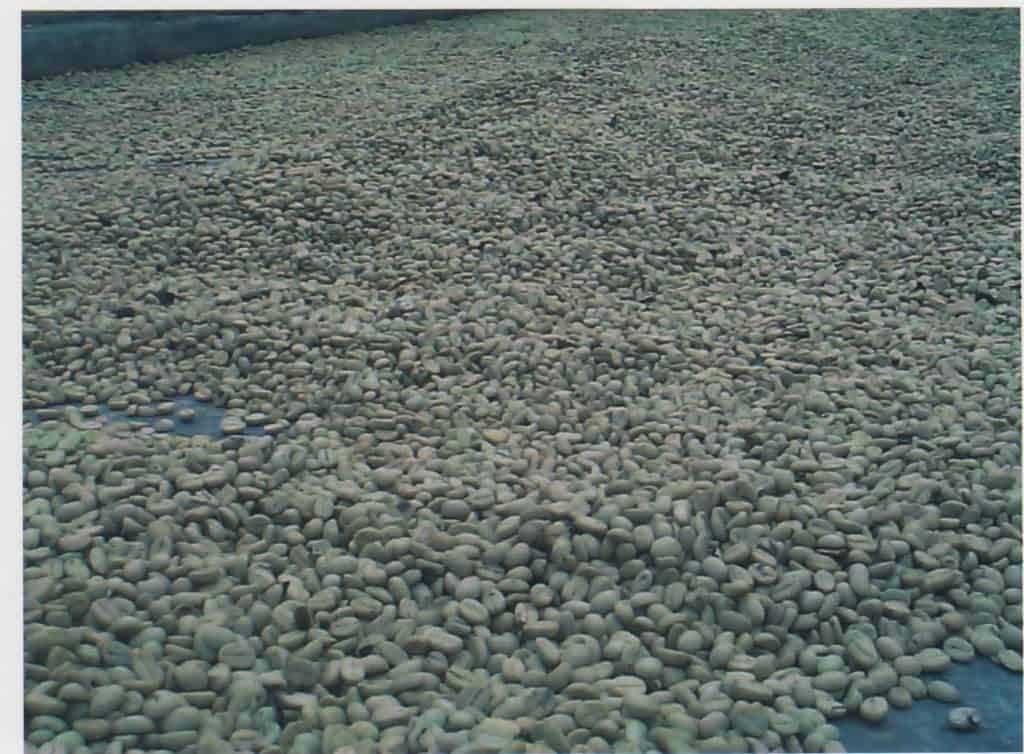

Drying coffee

A parchment, known as “pergamino” is present on each individual bean after the mucilage is removed from the outside of the bean. This pergamino, while wet initially is spread out over the drying patios for drying in the sun.

This pergamino, once dry gives the coffee an odd, lightweight feeling. The drying patios, are frequently constructed as a greenhouse, to trap the suns rays and accelerate the drying time.

In this below image you can see an example of the greenhouse type construction.

Drying the coffee is an important process that also requires diligence. On sunny days in particular it is necessary to rake and turn the coffee every 45 minutes to prevent one side of the bean from becoming too dry. This also can affect the sale price and ultimately the flavor of the bean.

In some cases, you might pool your harvest with neighboring harvests, forming a cooperative. The diligence of each farmer is essential so that the combined harvest retains the optimum regional quality and flavor.

2006 was an extraordinary year, with a tremendous coffee harvest, producing a strong double harvest. That year had one of the strongest coffee flowering events, "La Florecencia" that Colombia had seen in many years.

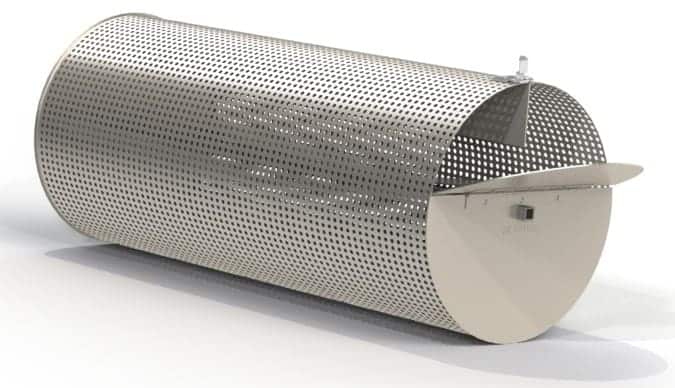

Coffee milling

The milling process is next to remove the parchment from the bean. This is usually done at a local business called a “trilladora”. This business will take the harvest and pass it through their machines removing the parchment for a fee. We needed to be careful however, as it was commonplace for the miller to recognize quality coffee and swap out 1/4 of your quality coffee for 1/4 garbage coffee. At the end of the day, would you know if you weren’t watching? We would place one of our representatives with eyes on the coffee throughout this whole process.

For those of you that have interest, (and a spanish understanding) I’m posting our procedures and quality control documents and processes for our production from harvest to transport.

In those years, we were cultivating, some 21 hectares of coffee throughout the region. We had worked very hard that year, bringing in certified agronomists to work with the coffee, applying custom mixes of fertilizer and pruning. We eventually had some of the #14 Cup of Excellence coffees that year.

No amount of efforts will take the place of mother nature. Sometimes things just aren’t in your favor. Sometimes the sunlight isn’t just right, or the rainfall is off that year, or the soil PH was uncorrectable. That’s the odd thing is that one year a farm will produce the best coffee in the world and the next year, it’s just terrible. Now chances are it will be pretty good, it’s just that it changes all the time, and one great year doesn’t necessarily predict a good year next year.

Quality control is essential for exports and penalites are steep if you fail to maintain the highest standards of quality required by the Federación.

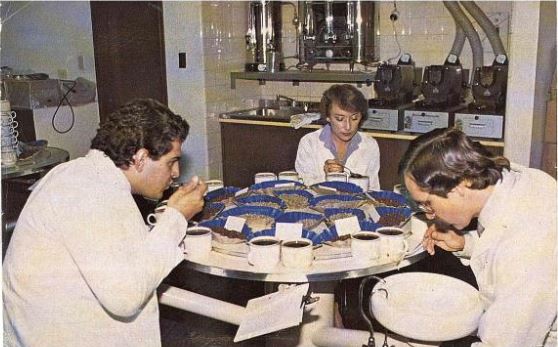

Cupping of the coffee is equally important. If the coffee doesn’t score well, then it won’t sell well. We attended classes by world-renowned cupper Lelly Espitia in Bogotá. Lelly is a wealth of information and experience in cupping. She taught us over a number of sessions the proper methods of cupping in her classes. Have a look at some of our cupping guidelines in Spanish from her class. Perhaps one day I’ll translate them for you!

Once the coffee is milled it is prepared for transport at the port of choice, usually Buenaventura, Colombia, or potentially Cartagena although this was further away for us. At any stage hereafter, proper care is important for transport of the green coffee. High in moisture content, it will absorb any odors it is around. Diesel exhaust, cattle recently hauled in a truck can taint the flavor of your coffee and can be detected by a skilled cupper.

We had visitors desiring to buy coffee from the source from all over the world. Canada, Japan, The United States, and Jordan. The closest estimate we had was 75 sacks of coffee warranted direct export by us to the client. Our export goal however was 300 sacks per 20 foot container.

In 2009, family pressures from the states, as well as the unpredictability of working with the Colombian government and controlling many different factors over the constantly shifting Colombian political landscape drove us back to American soil.

Meanwhile, building of the RK Drums brand continued to progress thanks to Ron Kyle’s lasting legacy. It became a more attractive endeavor, closer to home, capitalizing on my own personal coffee passions. The knowledge and experience I gained in Colombia over those 6 years I still apply even today within each and every customer transaction.