E. Coffee Loading

The loading of the coffee can be made easy or made more difficult depending on how you do it. Let’s do it the easy way.

|

Check out the BARGAIN BIN for scratch and dent equipment!

|

The loading of the coffee can be made easy or made more difficult depending on how you do it. Let’s do it the easy way.

It is important to understand that each of the RK Drums (4, 6, 8 and 12) will roast with approximately the same results at a

Your Roast has now begun. Start your stopwatch or wristwatch and monitor your time. Your temperature will have dropped after opening the lid, this is

As 1st crack subsides, the coffee will slowly cease to pop, the smoke will all but completely subside and the only thing you will hear

THE DRUM IS SUPER HOT, WEAR PROTECTION As 2nd crack is fully established, lets pull the coffee (You can pull it earlier or later around

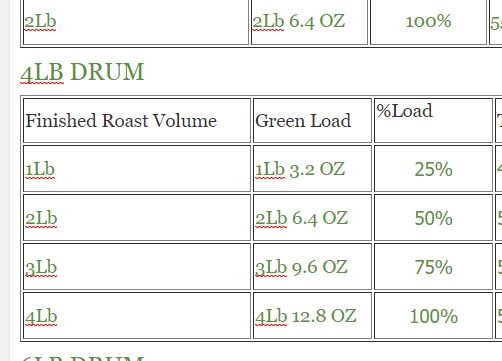

2LB DRUM Finished Roast Volume Green Load %Load Temp Est. 1st Crack Est. 2nd Crack 1/2LB 9.6 OZ 25% 470 6 mins 10 mins 1Lb